MAY 13 | 11:00 A.M CST - 45 min

Plastic Part Optimization Before Mold Design

—

In this webinar we will showcase how part and mold designers can utilize injection molding simulation quickly and efficiently to identify common plastic design issues early in the design cycle, without a mold design.

We will cover—

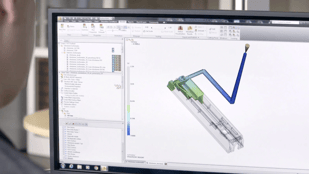

MAY 27 | 11:00 A.M CST - 45 min

How Mold Cooling Affects your Part Performance and Cost

—

Here we will discuss the important aspects of the mold cooling design on molding efficiency, and will also highlight how decisions on this design aspect actually influence the end performance of your plastic part. These points will be illustrated through practical engineer calculations and validated through case studies.

We will cover—

How making small improvements in cycle time can have a dramatic impact on total efficiency and, ultimately, the bottom line.

How by scrutinizing each stage of production time helps mold engineers manage the trade-offs between productivity and part quality.

———.png?width=338&name=Screenshot%20(4).png)

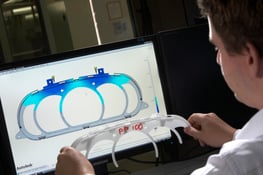

JUN 3 | 11:00 A.M CST - 45 min

Reducing Plastic Part Warpage using Moldflow®

—

This webinar will highlight how utilizing injection molding simulation allows designers and engineers to look into the entire mold and diagnose the root cause of the warpage. Ultimately, using simulation helps find solutions faster that yield higher quality parts that reach the market faster.

We will cover—

What are the main factors that drive warpage in plastic parts.

How to use simulation to isolate the root cause of warpage.

Workflow to incorporate windage (anti-warp) into your model to generate a dimensionally correct part.

———

![]()

Learn how D3® and Moldflow® can optimize your design and manufacturing capabilities.