Telecom Company

"...we killed a bi-weekly meeting for 10 people that was 2 hours long...it's not needed anymore!"

Explore how others have used the Lean Enterprise methodology to increase efficiencies & optimizes every area of a manufacturing business.

"...we killed a bi-weekly meeting for 10 people that was 2 hours long...it's not needed anymore!"

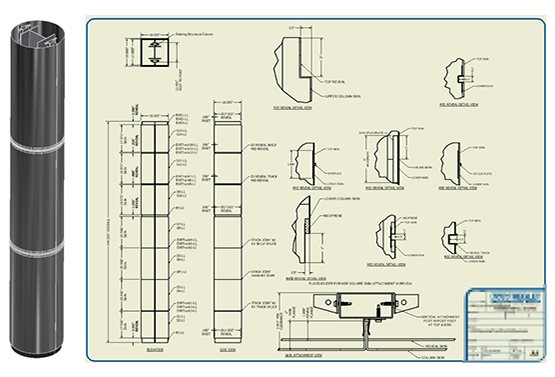

Column cover manufacturer takes 14hr process down to only 3 minutes.

Custom jewelry display and retail store fixture manufacturer, Pacific Northern, bridges the gap between their creative and mechanical teams and automates their product development process in Autodesk Inventor.

American manufacturers are shying away from cookie-cutter goods and services, and instead finding niche markets and opportunities to export high-end innovation to China.

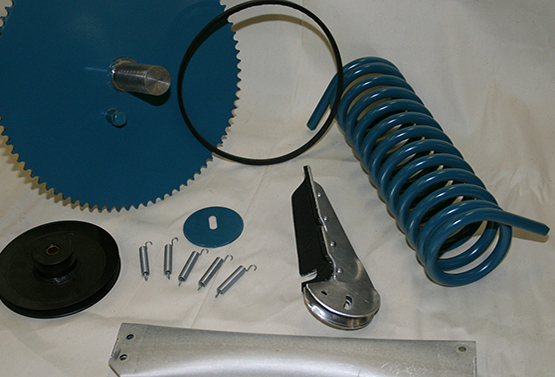

Master Pitching Machine uses the Autodesk engineering & design solutions and CAD support from D3 to create machines that approximates a human-like pitch.

RND Automation placed Fusion 360 in the hands of their machinists to streamline their manual processes.

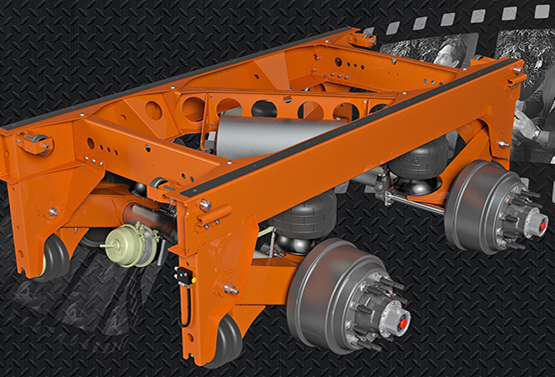

A Conversation with Jason M. Klein, Innovator & Co-Founder of Cush Suspensions.

Lifeform Studio, located in Leawood, Kansas, merges 3D photography and 3D printing to create life-like reproductions of people that they call lifeforms

Cynergy Ergonomics Uses Autodesk Inventor as a Powerful Tool to Win Bids, Design and Complete Projects

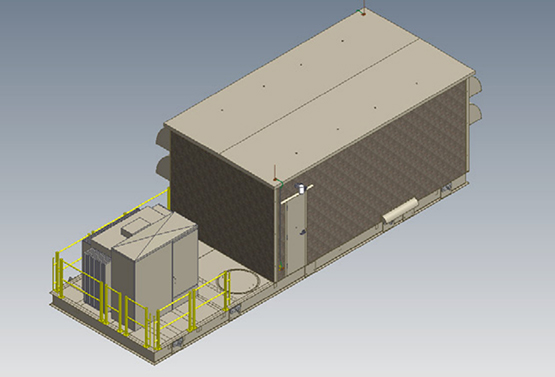

Based in Louisiana, CellXion is a division of Sabre Industries, Inc., the largest telecom shelter manufacturer in the world.

In order to help design and plan handling systems or conveyors, HSC uses Autodesk Inventor and Autodesk AutoCAD.

Since their inception in 1994, Northwind’s design team has been using the best in CAD software to design products to fulfill their customers’ needs.

Isotec Security Inc. designs, tests, and builds some of the world’s most trusted safety entrance systems that combat and prevent acts of terrorism with automated security that functions independently or as part of an integrated security solution.

PSI partners with D3 Technologies and utilizes several Autodesk products such as Product Design Suite (now referred to as the Product Design & Manufacturing Collection) and AutoCAD P&ID to accomplish tasks.

Before Bad Boy Mowers’ designers began using Inventor, they built each single part, tested it, and fit it together until they had a finished product, a painstaking process that was cut dramatically by the addition of 3D design.

GENESYS is a material-handling systems integrator that specializes in engineering, design-build and construction.

"We needed this investment to take us to the next level. D3 had everything we needed and provided us with support that was close by."

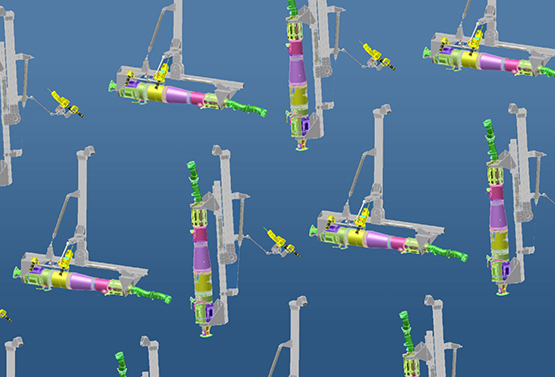

Ultrax Aerospace Inc. got their start in 1995 as a software and hardware developer for military testing equipment.

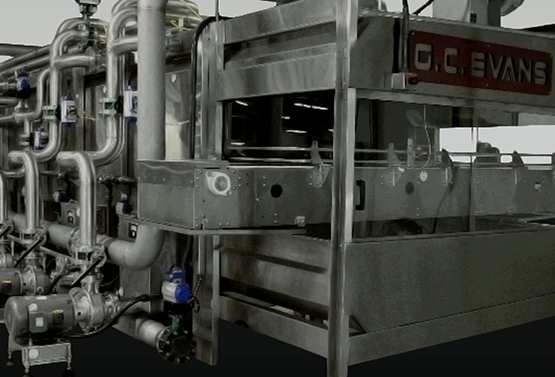

"Making the transition to Autodesk Inventor was made much easier for G.C. Evans thanks to their partnership with D3 Technologies."

By using 3D design in Inventor, they were able to greatly improve their precision, an important factor when working with laser cutting technology.

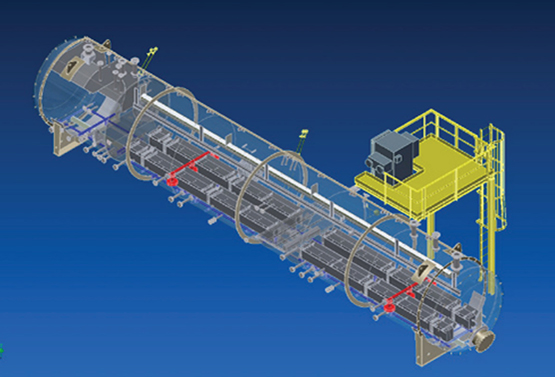

With Autodesk Inventor Automation Professional and Autodesk Consulting, NATCO now takes just minutes to generate digital prototypes, drawings, schedules, and parts lists for manufacturing.

"We noticed that there were quite a few highly competent manufacturers of this type of equipment, but none of them were very good at after-market service.""

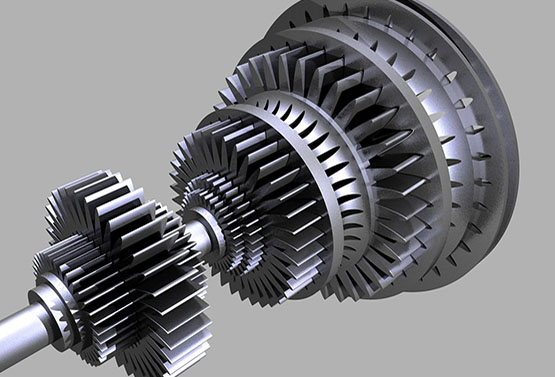

Parker Hannifin turned to Autodesk for one of the main product design tool sets it uses throughout its global enterprise.

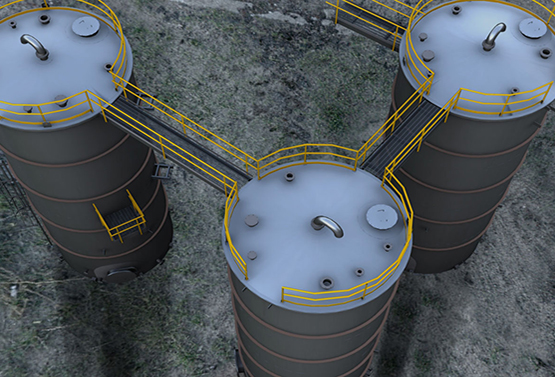

Pala Interstate uses Autodesk software and D3 Automation to design and build more storage tanks, faster.

With Autodesk Inventor Engineer-to-Order (Previously Called Autodesk Intent)and Autodesk Consulting, Evans Consoles quickly generates digital prototypes for manufacturing technical furniture and consoles designed for command centers and air-traffic control rooms.

Cush Suspensions finds an all-inclusive ERP solution to overcome the challenges of managing product inventory.

Autodesk is the latest sponsor to join Top EV Racing, providing software and support to bring to life critical vehicle components designed by Top EV Racing’s engineers.

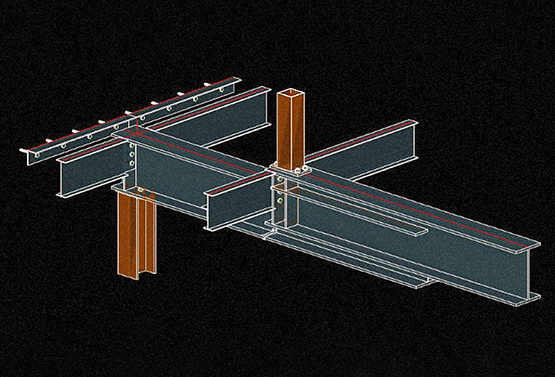

With the help of Autodesk® Advance Steel, a Massachusetts firm dramatically reduced rework time on complex projects.

AutoCAD Electrical to execute new designs, and already the solution is doing more than just helping them design high-quality, durable machines: AutoCAD Electrical has reduced schematic and layout errors by 90 percent and design costs on projects by 25 percent, making Osgood more competitive.

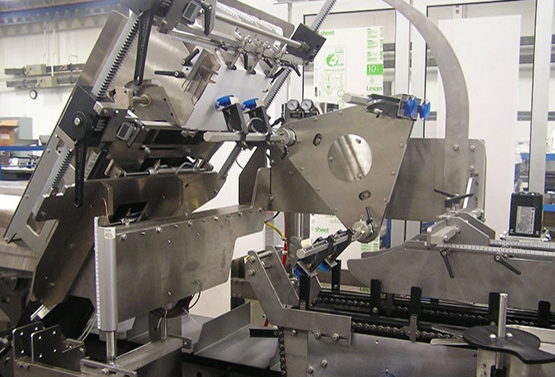

OYSTAR Jones realizes time savings of up to 75 percent in designing high-speed custom packaging equipment by using AutoCAD Electrical software.

Known for its inventive engineering and willingness to tackle technically challenging projects, Mammoth, Inc., has been delivering custom heating, ventilating, and air-conditioning equipment for more than 65 years. .

Pressure Vessel Industry Puts Web Based Engineer-to-Order Sales in Motion 85% Faster.

The Autodesk TruNest product was the winning solution to address the critical workflow issues Custom Engineering was facing. Taking a single drawing completion went from 2-3 days to 2-3 hours.

© D3 Technologies, All Rights Reserved.