Generative Design is the Future and the Present

When I started using CAD, it was really just Computer Assisted Drafting. There were some productivity tools for creating the linework efficiently, and editing drawings was much faster, but the entities on the screen had no more value than lines inked on vellum. Then, we moved into the era of Computer Aided Design. For thirty years, the industry has been the focus of 3D CAD, CAM, and CAE workflows where a human manipulates some powerful software to convert what they imagine to geometry on a screen they hope will solve a problem. The model can then be visualized, analyzed, documented, and used to program the method of its production. While effective, all of this is still very much a serial process, and the discovery of a problem along the way can cause the whole process to restart. To reduce the likelihood of that happening, engineers and designers try to keep the changes to the design to a minimum or play it safe or just use extra material for safety. What is different in this new way of doing things is the ability to combine the needs of the design, materials that you have access to, production methods you can use, and optionally cost targets into one parallel process, which generates a complete, manufacturable model from the beginning.

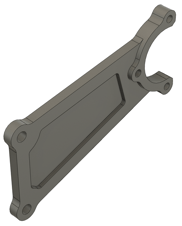

Today’s reality is that most companies are still making components that can be produced with manual mills like the one below. The reason is that they’re affordable, relatively easy to produce, and perform as needed. This has worked for decades, but times are changing, and more and more manufacturers are dealing with the costs of using more material than necessary and discovering that overbuilding in one area causes a need to overbuild in other areas leading to a bloated design that is inefficient to produce, transport and maintain.

In the past few years, most of the major players in the engineering and design software space have been throwing the term ‘Generative Design’ around in a variety of ways. Claims this new technology is the next phase of the product development process are true, but they’re generally accompanied by striking images of mechanical components that most manufacturers can’t make. This is unfortunate for everyone, especially smaller or traditional manufacturers who could be leveraging Generative Design without having to buy new manufacturing equipment.

There are also tools that refer to themselves as Generative Design, but they’re just shape optimization based on a model that you have already built. The optimized shape result might include geometry that isn’t manufacturable, and what manufacturing process inputs you’re offered are going to be limited. A truly GENERATIVE Design workflow begins with only the geometry needed to secure a component place or that needs loads applied to it. There is no requirement in a Generative Design mechanical study to have a “starter shape” or boundary to stay within. It is an option, but it should be a choice. Instead of using a predetermined shape to stay within, you can instead define geometry as obstacles to be avoided and let the system offer suggestions on how. You can even add specialized obstacles for fasteners that will hold the geometry in place and include clearances for tool access.

In the example below, you can see the critical geometry of the component in green and the loads that are applied in blue. The yellow arrow is defining the load of gravity, and the two cylinders on the left are fixed in place.

After defining the basic geometry, you can list the materials you want to explore. There is a large library, and it will include some exotic materials, but you can select the materials you commonly have on hand or know you have reliable access to. Then you move on to the manufacturing processes. In a proper Generative Design process, you can define multiple approaches to creating the component, and you can be specific. Rather than saying a component will be “machined,” you can state if it will be produced using 2.5, 3, or 5-axis milling, 2D cutting, Die Casting, and from which directions you would like the tool to approach or the die closed from. Of course, you can include additive processes with the same level of control if you have the equipment to produce those components or if you’re trying to see if acquiring them is justified by the improvements they could offer. All of this ensures that any results created by the study are something you can produce.

The final step is to define the mass or stiffness goals for the component and send it to the cloud for parallel calculation of all the options and combinations of material and process. The ability to do all these studies at once is another element that stands out for a true Generative Design. Once started, the cloud-based engine will begin to generate a series of components that you can review while they’re still calculating. You can review the outcomes, filtering them based on material, manufacturing process, and even cost. The results can be compared individually, side by side, or as a group using a chart. After you’ve reviewed the options, you can export a component that will do the job, and you can produce today like the component below, which was optimized for 2.5-axis milling with better performance than the original design and less weight.

Autodesk’s Fusion 360 is a great platform for real Generative Design. If you would like to know more or see how it would work for your products, please reach out to Team D3.